GPPS Sheet

Extruded PS sheet,Polystyrene Sheet

GPPS sheet also called PS sheet, Polystyrene Sheet.GPPS sheet was made by raw material of General-Purpose Polystyrene and manufactured on automated machinery.GPPS sheet has high clarity, easy to process, low humidity absorbs rate, low cost, and high hardness characteristics. Because GPPS material has low humidity absorb rate, therefore, this material has widely used on shower doors, also this material is cost-effective compared to acrylic material. Kao-Chia provides three types of GPPS sheets, flat, pattern, and diffuser.

Product Application

GPPS flat sheet can be used on indoor decoration, photo frame, indoor partition screen, replace window glass, prevent dust.

GPPS pattern sheet can be used on shower doors, shower screen, office partition, sliding door.

GPPS diffuser sheet can be used on LED light panels, Fluorescent light covers.

Please scroll down to find the GPPS sheet of your need.

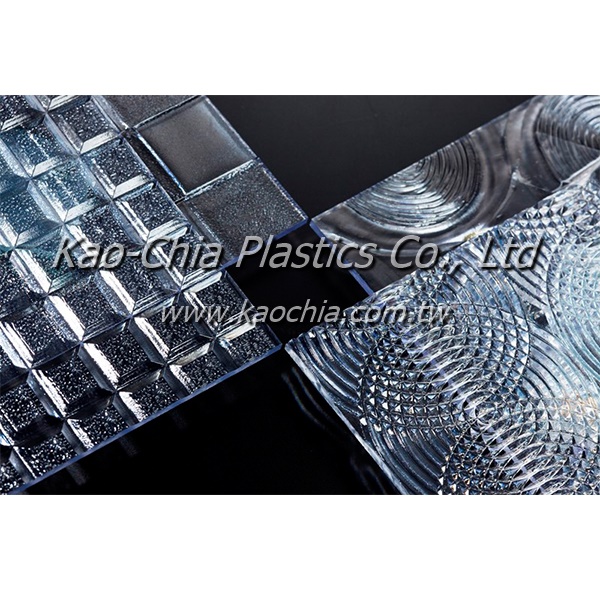

GPPS Patterned Sheet

GPPS Patterned Sheet was made by raw material of general-purpose polystyrene and the pattern...

GPPS Patterned Sheet pattern list

In Taiwan we now have over 46 different patterns for clients to choose from, please scroll...

Taiwan GPPS Flat Sheet

GPPS Flat Sheet has some advantages such as high in clarity, easy to process, cost-effective,...

GPPS Diffuser Sheet

GPPS diffuser sheet has been widely used on LED panel these recent years, GPPS diffuser is more...

GPPS Sheet - Extruded PS sheet,Polystyrene Sheet | Over 41 Years Production Experience of PE Blowing Film, GPPS Sheet & Acrylic Sheet Extrusion Technology | Kao-Chia Plastics Co., Ltd.

Based in Taiwan since 1990, Kao-Chia Plastics Co., Ltd. has been an ISO certified protective film and coating manufacturer and exporter. Their main products, including GPPS Sheet, GPPS sheet, Acrylic sheet, PMMA sheet, PE protective film, in particular with the capacity of producing 300 tons/month acrylic sheets.

Kao-Chia has been established for 32 years, but we have 42 years production experience of PE blowing film, GPPS sheet and Acrylic sheet extrusion technology. Our concept of considering both quality and service equally important and performance gain trust from customers. Kao-Chia not only manufactures GPPS sheet, Acrylic sheet, PE products, but also provides high quality and perfect after-sales service.

Kao-Chia has been offering customers high-quality PE film, GPPS sheet and acrylic sheet, both with advanced technology and 32 years of experience, Kao-Chia ensures each customer's demands are met.