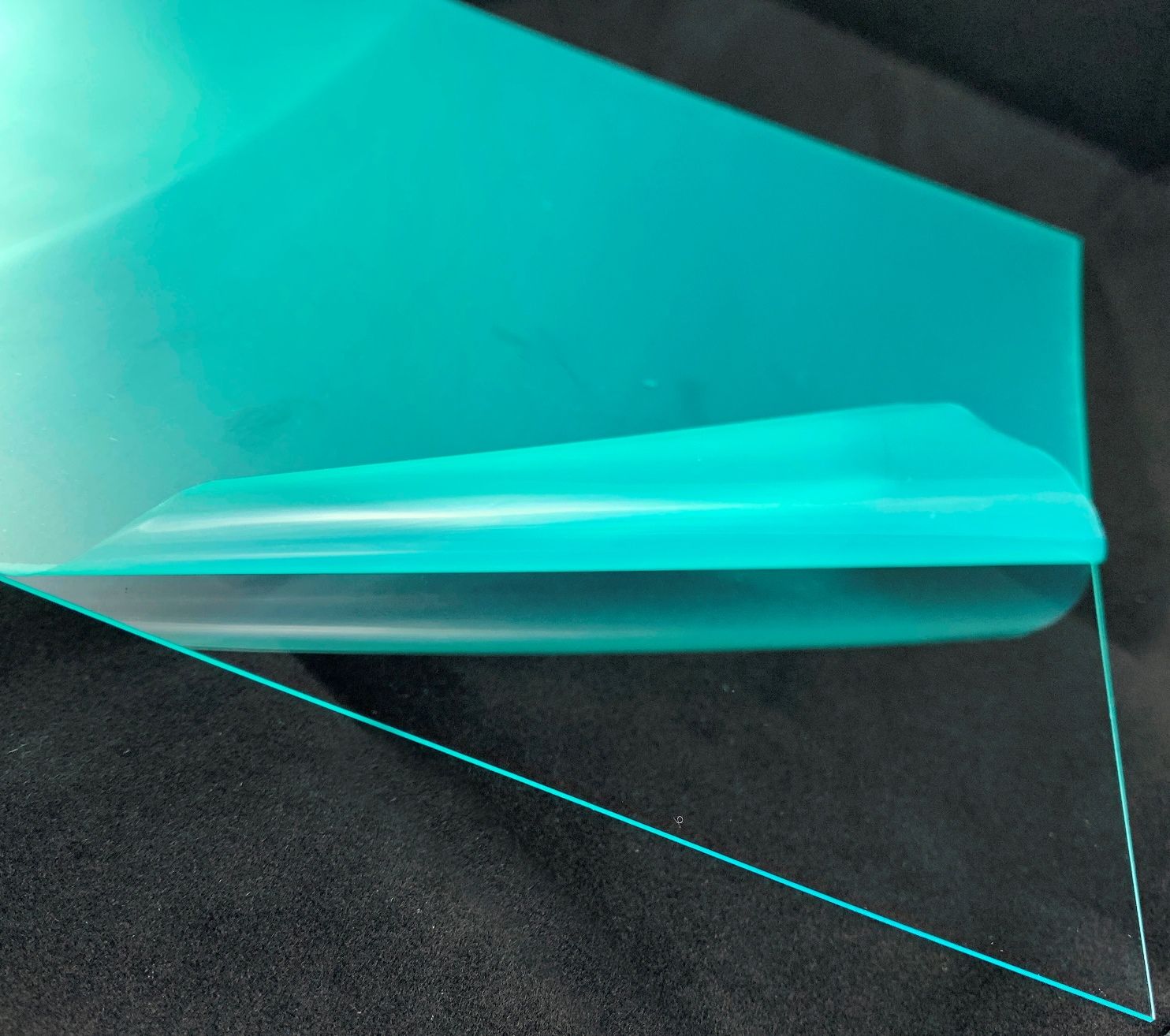

How to choose PE protective film?

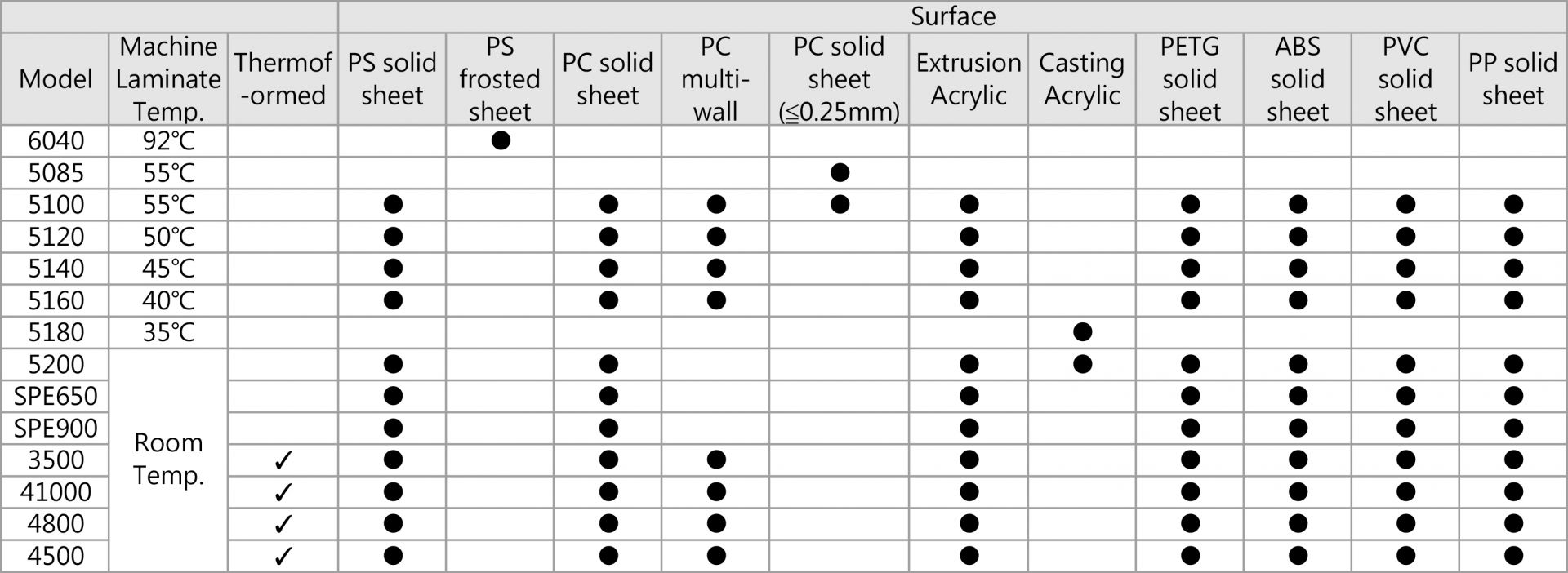

According to commonly used materials, we narrow it down to a few types, here client could choose the model by comparing the surface and laminate temperature.

- Related Products

PE Protective Film-Common Low Viscosity

5100, 5120, 5140, 5160, 5180, 5200

PE protective film produces with extrusion, and the adhesion layer material and the PE substrate...

DetailsPE Protective Film-Common Middle Viscosity

SPE650

LDPE protective film produces with extrusion, and the adhesion layer material and the PE substrate...

DetailsPE Protective Film-Common High Viscosity

SPE900

PE film produces with extrusion, and the adhesion layer material and the PE substrate are co-extruded...

DetailsPE Protective Film-High Temperature Used Middle Viscosity

4500, 4600

LDPE film produces with extrusion, and the adhesion layer material and the PE substrate are co-extruded...

DetailsPE Protective Film-High Temperature Used High Viscosity

31000.0

PE film produces with extrusion, and the adhesion layer material and the PE substrate are co-extruded...

Details