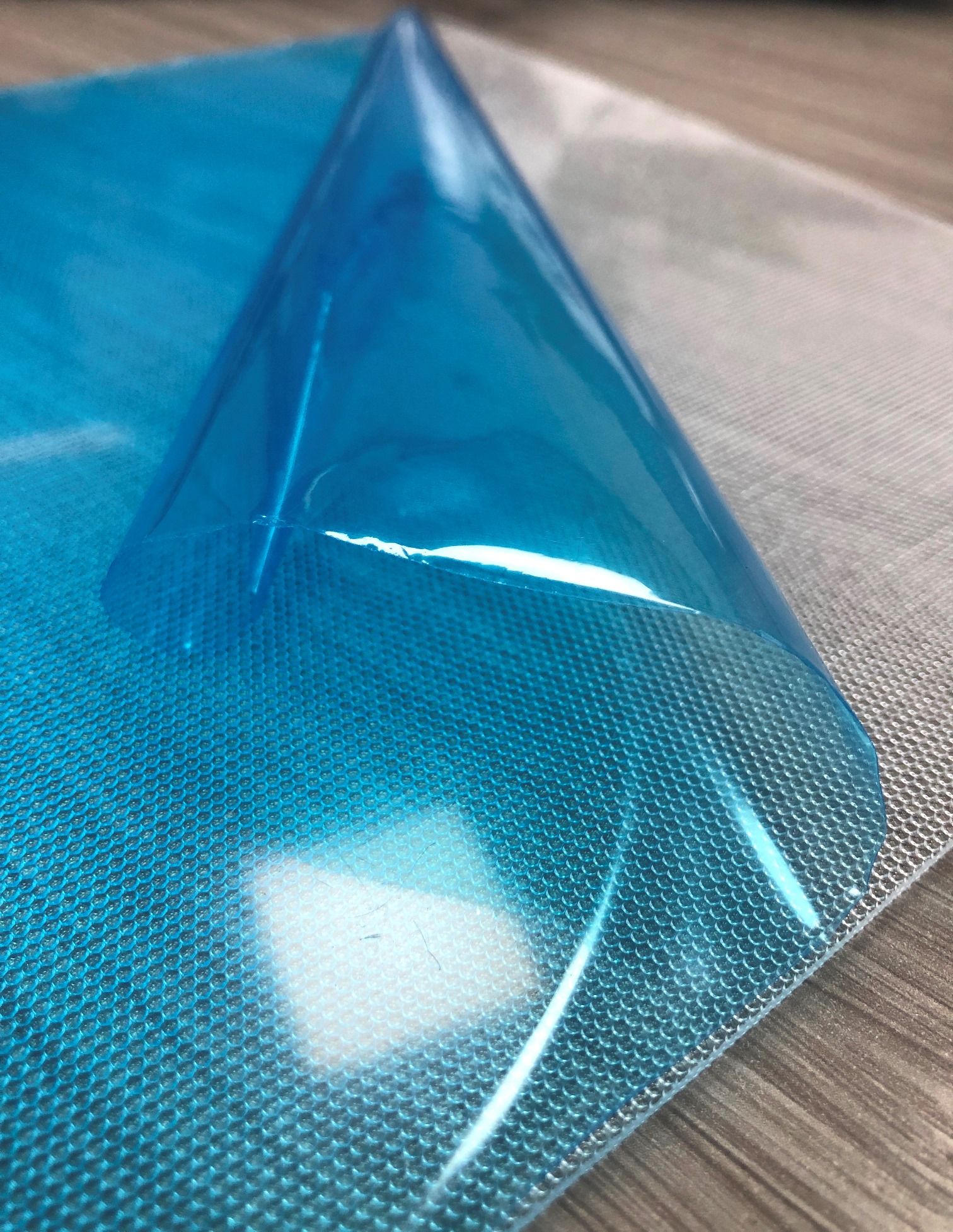

PE Protective Film

Polyethylene film

Kao-Chia's self-adhesion PE protective films are high clarity, environmentally friendly, non-toxic, low absorbing rate, impact-resistant, and in complying with FDA regulations. Kao-Chia's protective film can protect flat sheet from scratch and isn't glue base which will not leave residue on the plastic sheet, films stick on the plastic sheet by itself. We provide regular and heat-resistance film also a variety of film viscosity for clients to choose from moreover it's printable.

Product Application

Self-adhesion PE protective film is suitable for all kinds of plastic flat sheet, such as PC, PP, PS, PET, PVC, Acrylic sheet, general paint steel sheet, glossy stainless sheet, glasses, according to laminated temperature choosing the correct protective film stickiness can reduce product lost, and can also reduce products scratches, normally PE protective film can laminate by hand or by extrusion machine.

Please scroll down to find more products.

PE Protective Film-Common

It produces with extrusion, and the adhesion layer material and the PE substrate are co-extruded...

PE Protective Film-High Temperature Used

It produces with extrusion, and the adhesion layer material and the PE substrate are co-extruded...

PE Protective Film - Polyethylene film | Over 41 Years Production Experience of PE Blowing Film, GPPS Sheet & Acrylic Sheet Extrusion Technology | Kao-Chia Plastics Co., Ltd.

Based in Taiwan since 1990, Kao-Chia Plastics Co., Ltd. has been an ISO certified protective film and coating manufacturer and exporter. Their main products, including PE Protective Film, GPPS sheet, Acrylic sheet, PMMA sheet, PE protective film, in particular with the capacity of producing 300 tons/month acrylic sheets.

Kao-Chia has been established for 32 years, but we have 42 years production experience of PE blowing film, GPPS sheet and Acrylic sheet extrusion technology. Our concept of considering both quality and service equally important and performance gain trust from customers. Kao-Chia not only manufactures GPPS sheet, Acrylic sheet, PE products, but also provides high quality and perfect after-sales service.

Kao-Chia has been offering customers high-quality PE film, GPPS sheet and acrylic sheet, both with advanced technology and 35 years of experience, Kao-Chia ensures each customer's demands are met.